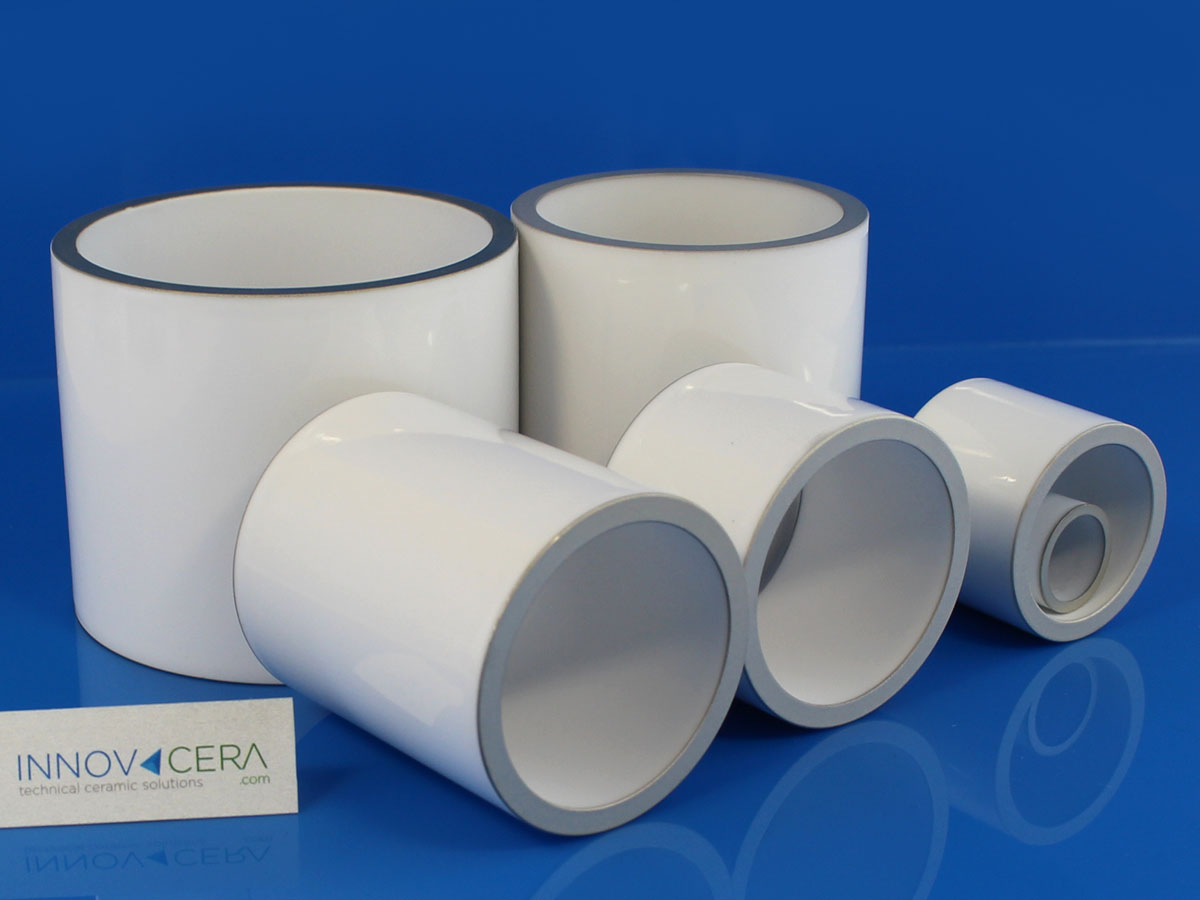

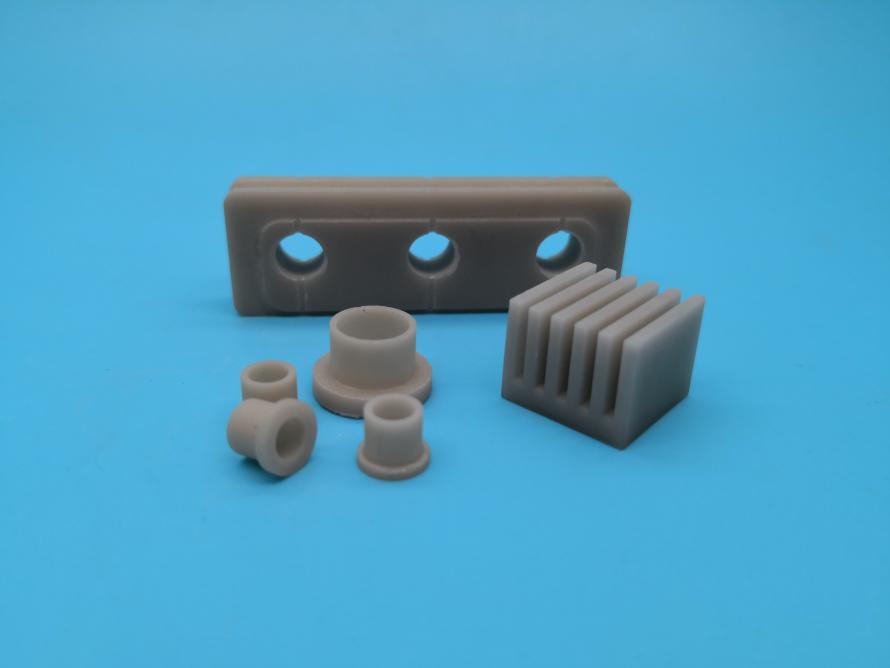

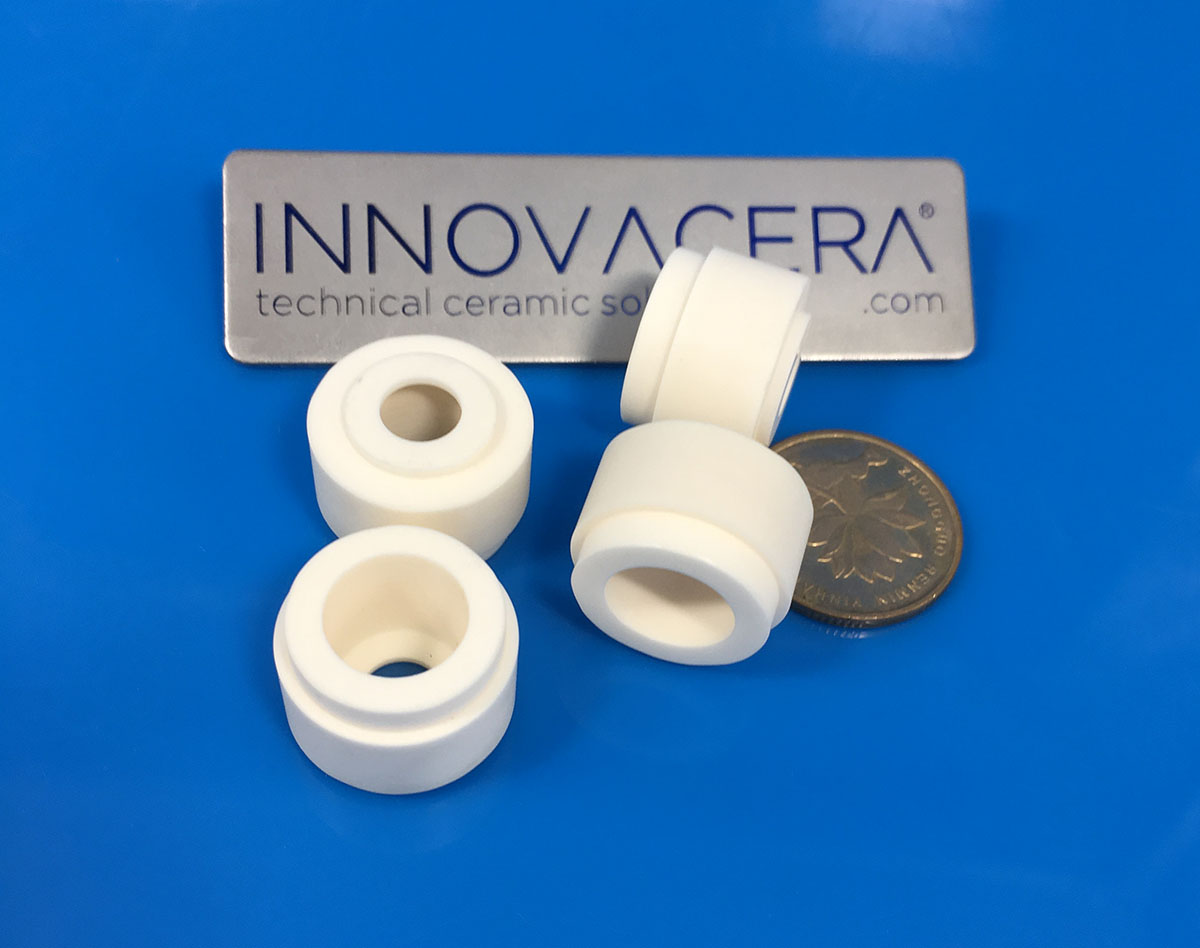

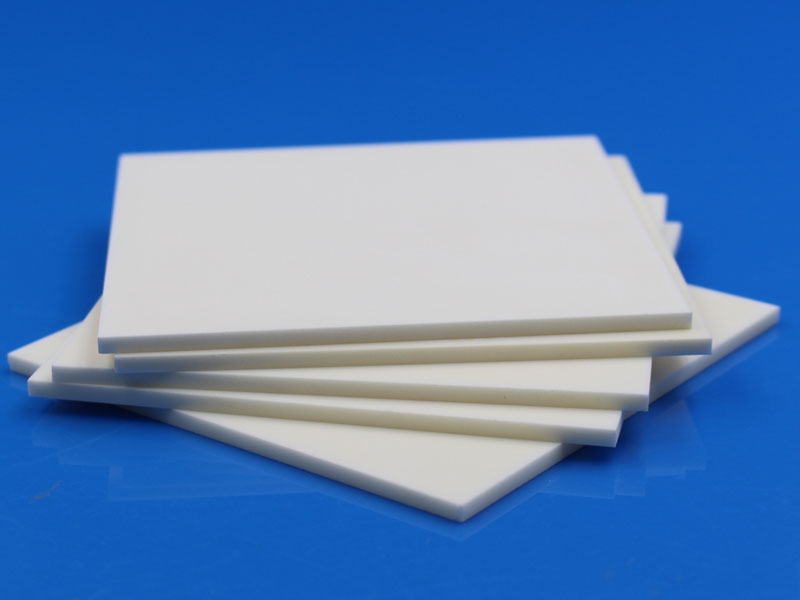

As a typical inorganic non-metallic material, ceramics seem to stand in a completely opposite position to metal.

As its advantages are too prominent, people began to think of combining ceramics and metals, to joint their strengths. This is how the Metallized Ceramics technology generation.

Advantages of ceramics

- Low dielectric loss-the dielectric constant.

- High thermal conductivity

- Thermal expansion coefficient-the thermal expansion coefficients of ceramics and metals are close

- High bonding strength-high bonding strength between metal layer and ceramic

- High operating temperature-ceramics can withstand high and low-temperature cycles with large fluctuations, and can even operate normally at high temperatures of 500-600 degrees.

- High electrical insulation-the ceramic material itself is an insulating material and can withstand a high breakdown voltage.

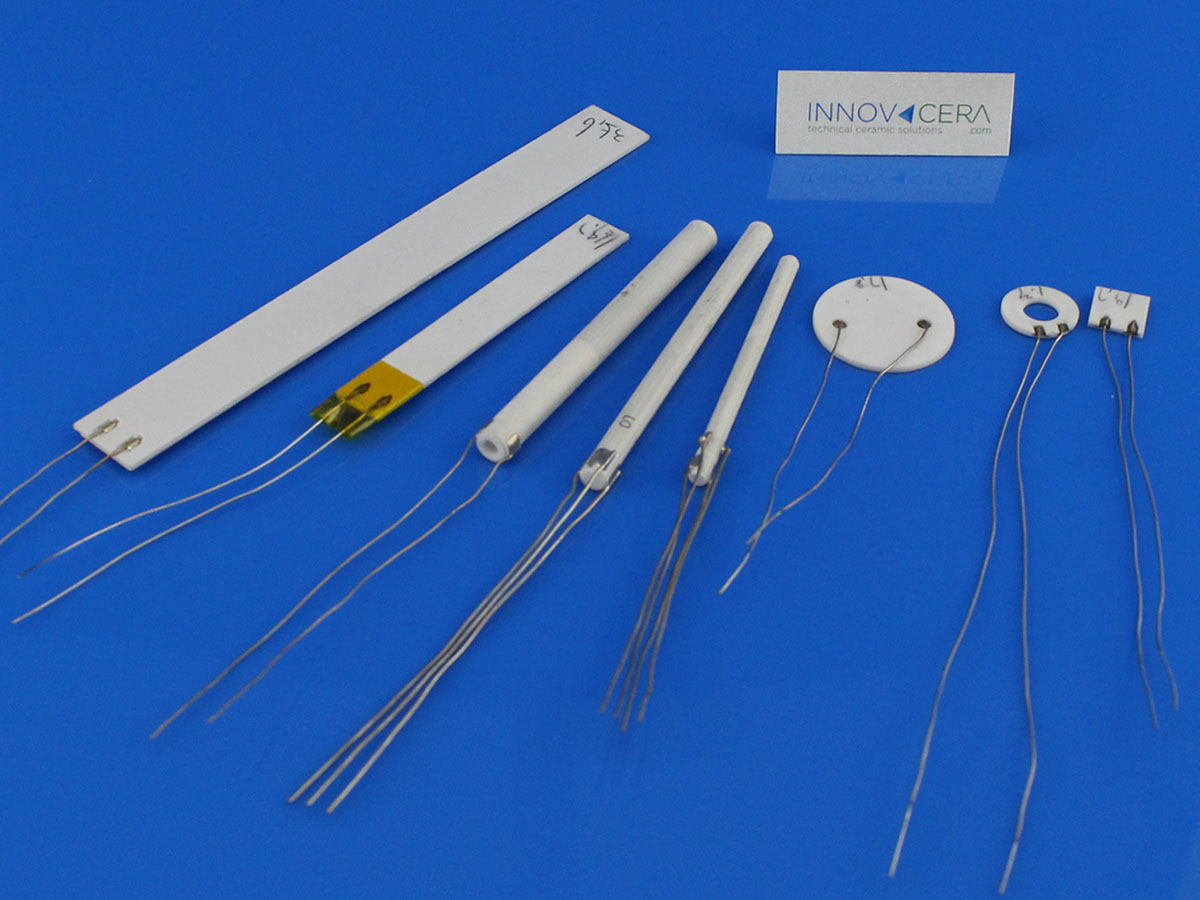

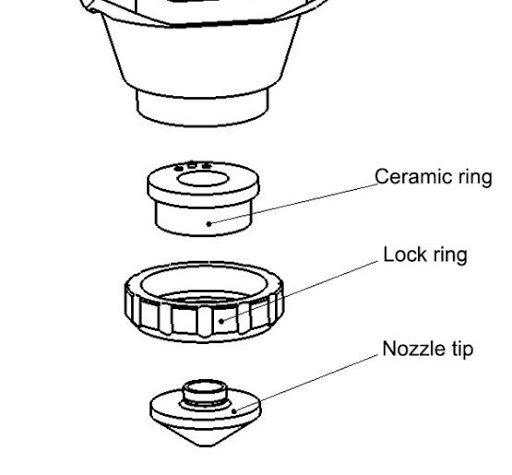

When ceramics are used in circuits, they must be metalized first, that is, a layer of metal film that is firmly bonded to the ceramics but not easy to be melted is applied to the ceramic surface to make it conductive, and then welded with metal leads or other metal conductive layers Connected to become one.

It can be said that the pros and cons of the ceramic metallization effect will directly affect the final packaging effect.

The commonly used preparation methods for ceramic metallization mainly include the Mo-Mn method, activated Mo-Mn method, active metal brazing method, direct copper-clad method (DBC), and magnetron sputtering method.

1. Mo-Mn method

The Mo-Mn method is based on refractory metal powder Mo, then a small amount of low melting point Mn is added to the metallization formula, the binder is added to coat the Al2O3 ceramic surface, and then sintered to form a metalized layer. The disadvantages of the traditional Mo-Mn method are that the sintering temperature is high, the energy consumption is large, and the lack of activator in the formula leads to low sealing strength.

2. Activation Mo-Mn method

The activated Mo-Mn method is an improvement on the basis of the traditional Mo-Mn method. The main directions for improvement are: adding activators and replacing the metal powder with oxides or salts of molybdenum and manganese. Both types of improvement methods are aimed at lowering the metallization temperature. The disadvantages of the activated Mo-Mn method are that the process is complex and the cost is high, but its combination is firm and can greatly improve the wettability, so it is still the earliest invented process in the ceramic-metal sealing process with a relatively wide range of applications.

3. Active metal brazing method

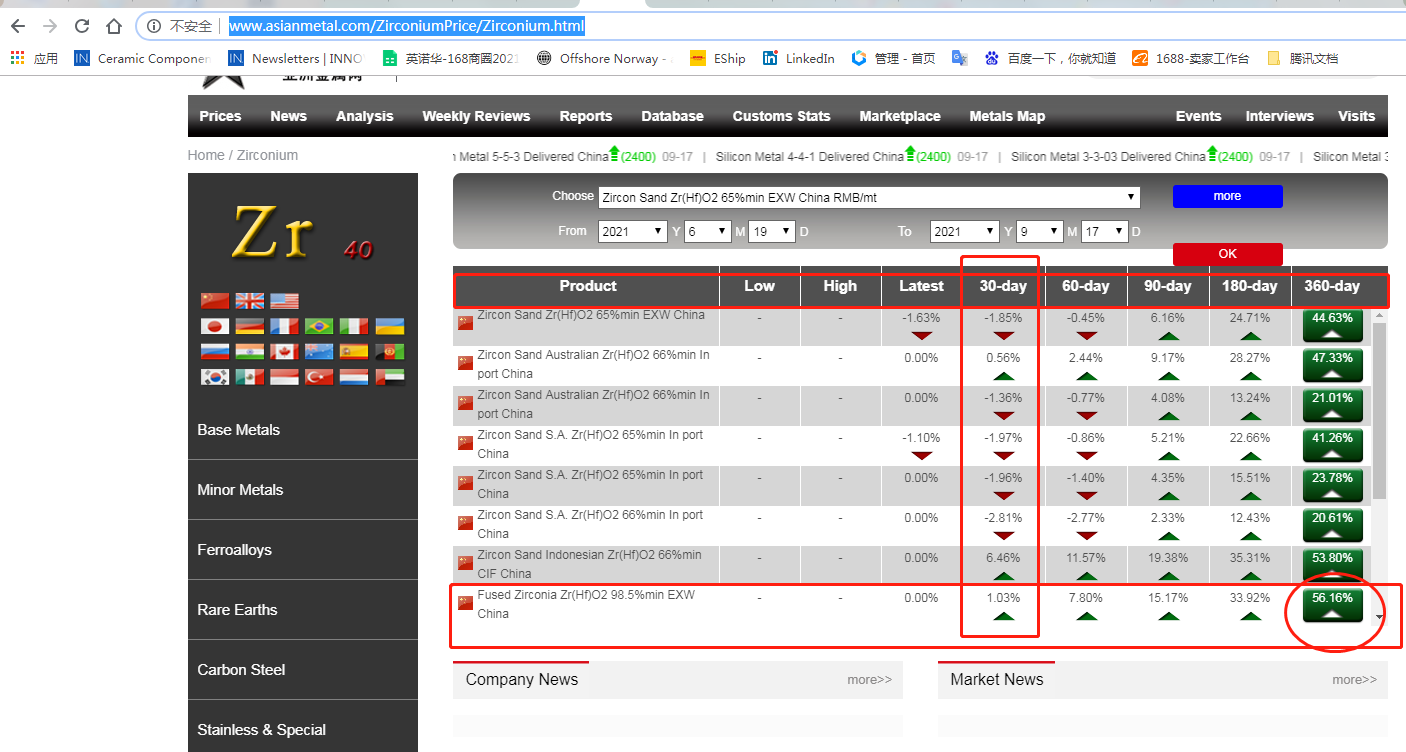

The active metal brazing method is also a widely used ceramic-metal sealing process. It is developed 10 years later than the Mo-Mn method. It is characterized by fewer processes. The ceramic-metal sealing can be completed by only one heating process. . The brazing alloy contains active elements such as Ti, Zr, Hf and Ta. The added active elements react with Al2O3 to form a reaction layer with metallic characteristics at the interface. This method can be easily adapted to mass production. Compared with the manganese process, this method is relatively simple and economical.

The disadvantage of the active metal brazing method is that the active brazing filler metal is single, which limits its application and is not suitable for continuous production. It is only suitable for large, single-piece or small batch production.

4. Direct Copper Cladding (DBC)

DBC is a metallization method for bonding copper foil on ceramic surfaces (mainly Al2O3 and AlN). It is a new type of process developed with the rise of chip-on-board (COB) packaging technology. The basic principle is to introduce oxygen between Cu and ceramics, and then form a Cu/O eutectic liquid phase at 1065~1083℃, and then react with the ceramic matrix and copper foil to produce CuAlO2 or Cu(AlO2)2, and then Under the action of the intermediate phase, the bond between the copper foil and the substrate is realized.

5. Magnetron sputtering method

Magnetron sputtering method is a kind of physical vapor deposition. It deposits multilayer films on the substrate through magnetron technology. It has advantages over other deposition techniques, such as better adhesion and less Contamination, and improves the crystallinity of the deposited samples to obtain high-quality films. The metallization layer obtained by this method is very thin, which can ensure the accuracy of the part size. The DPC process supports PTH (Plated Through Hole) / Vias (Through Hole). High-density assembly is possible-the line/spacing (L/S) resolution can reach 20μm, so as to realize the lightweight, miniaturization, and integration of the equipment.

As a new type of material, ceramic metallization has many unique advantages. In the near future, ceramic metallization materials are bound to shine.

Enquiry

Enquiry