Innovacera to Showcase Advanced Ceramic Solutions for Semiconductor Manufacturing at SEMICON Europa 2025 – Booth #C2/249

Innovacera is pleased to announce its participation in SEMICON Europa 2025, one of Europe’s premier trade shows for the semiconductor industry, taking place November 18–21, 2025, at the Trade Fair Center Messe München, Am Messesee 2, 81829 Munich. We welcome you to visit us at Booth #C2/249 to explore how our advanced ceramic solutions empower next-generation semiconductor manufacturing through precision, reliability, and superior thermal performance.

Pioneering Ceramic Solutions for Semiconductor Equipment

As the semiconductor industry pushes toward higher integration, smaller geometries, and greater thermal demands, material performance becomes a critical factor in achieving manufacturing precision and yield. Innovacera’s technical ceramics are engineered to meet these challenges—offering excellent electrical insulation, thermal conductivity, and dimensional stability under extreme conditions.

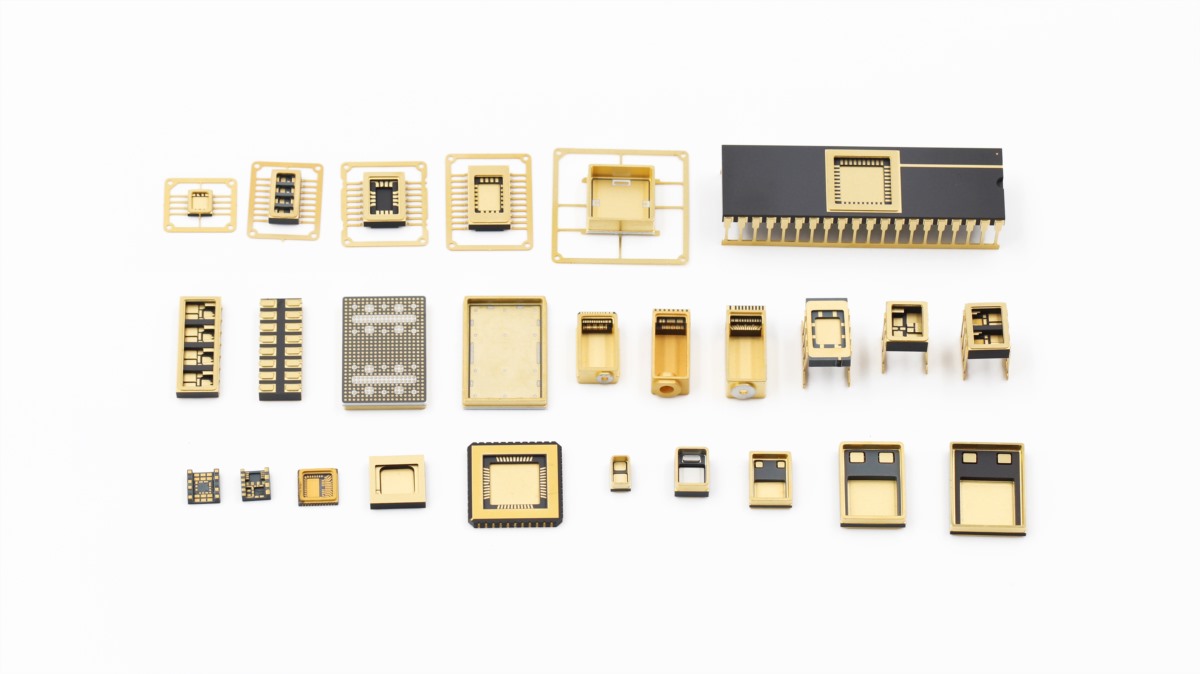

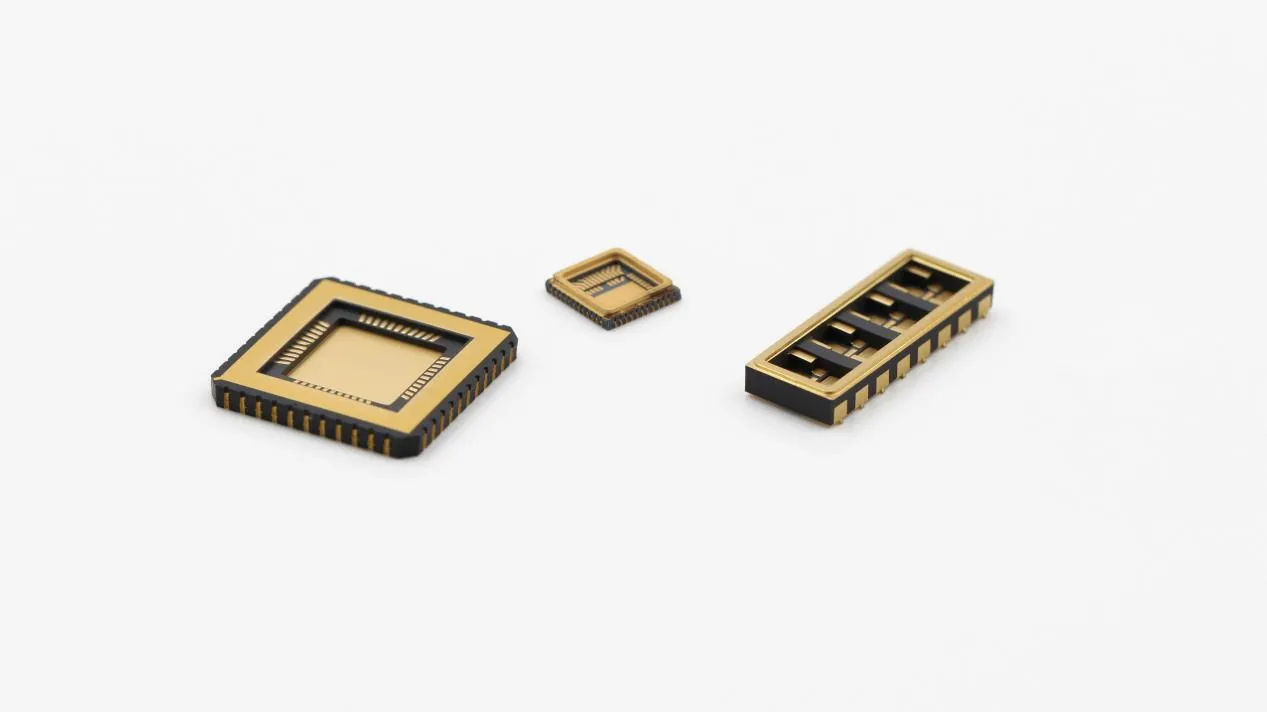

Innovacera’s Key Exhibits at SEMICON Europa 2025

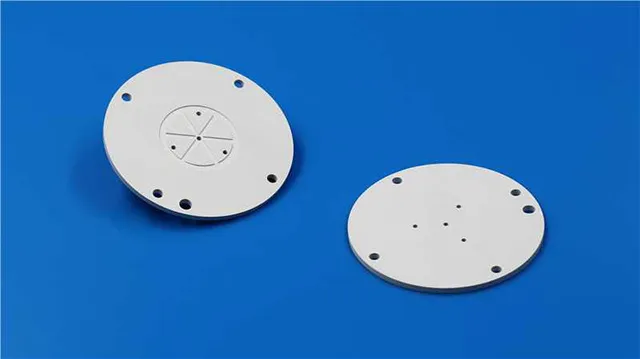

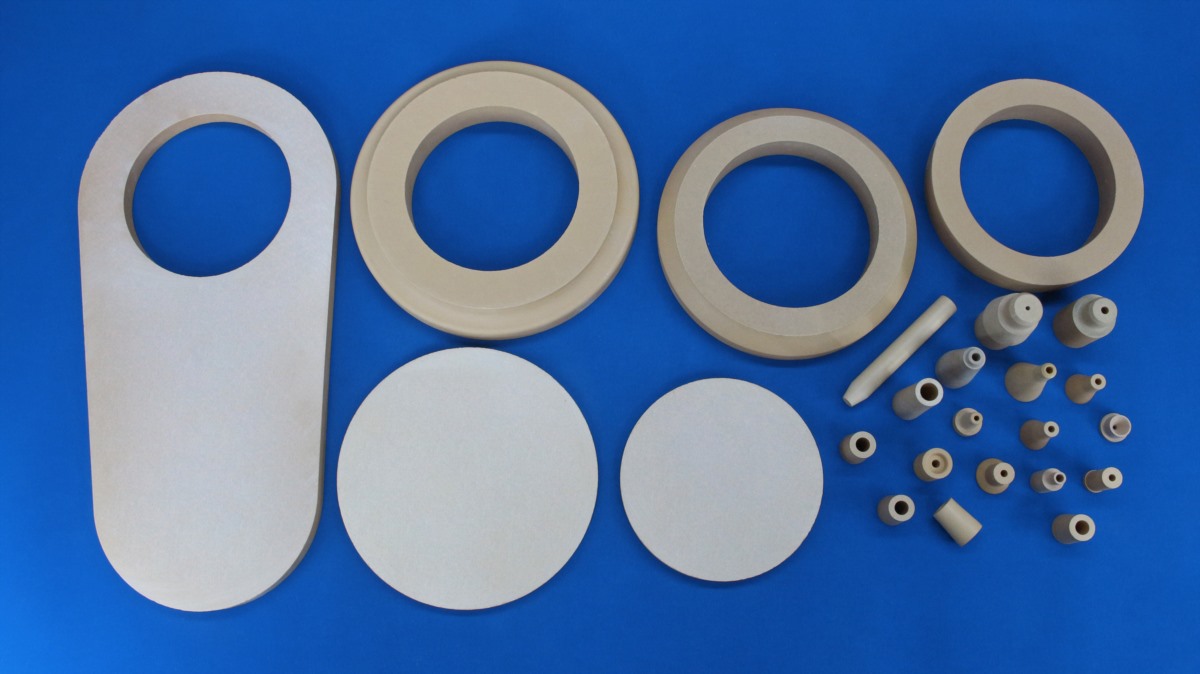

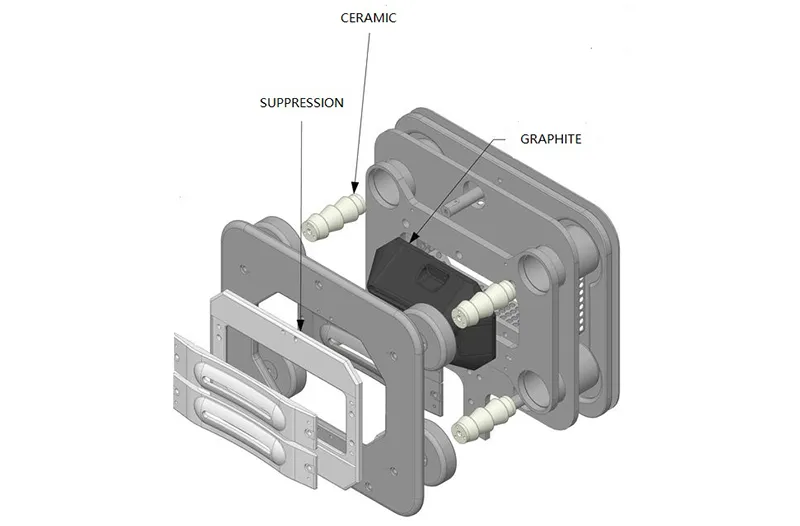

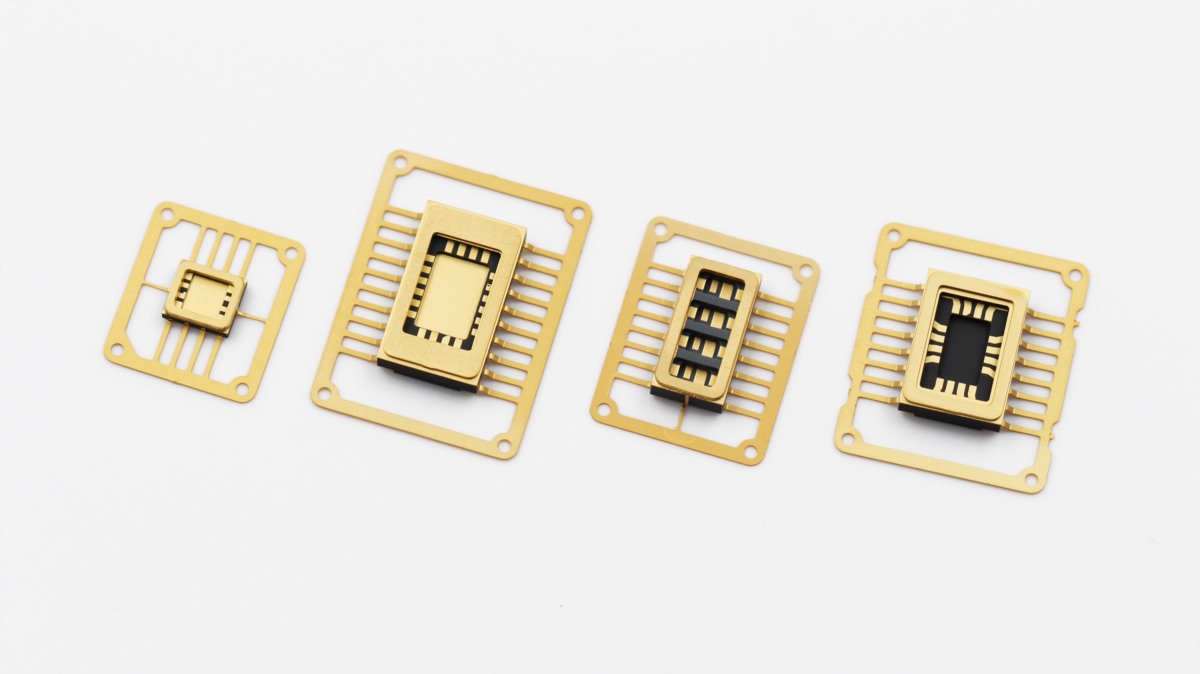

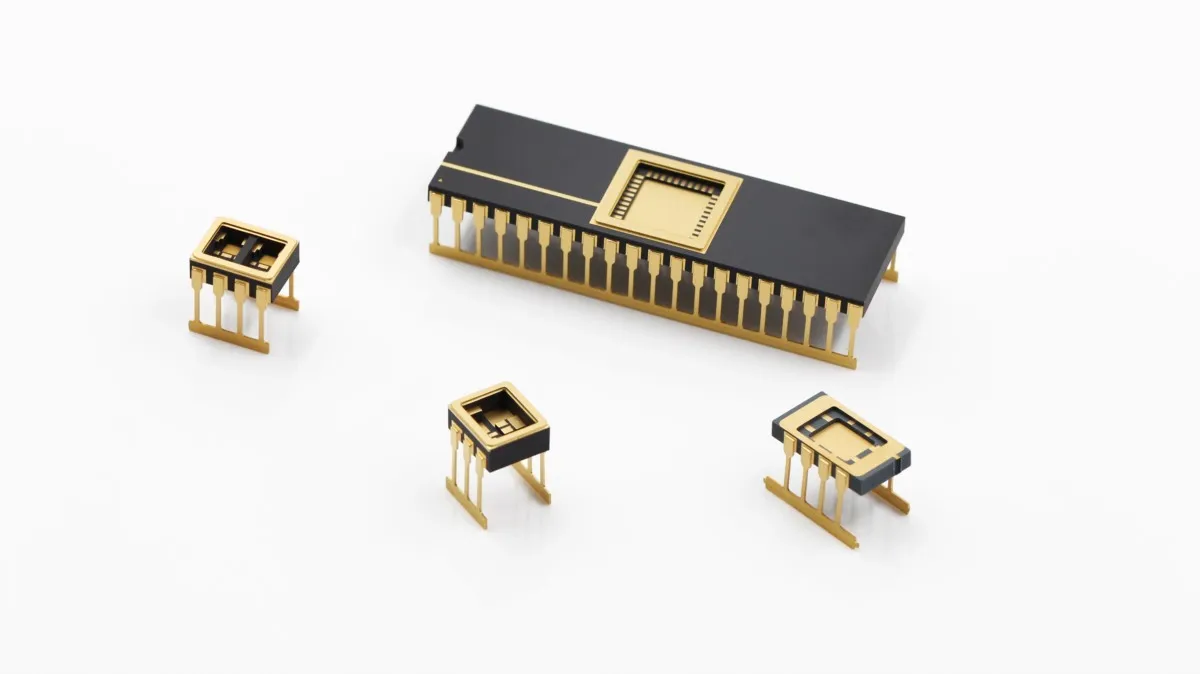

✅ Boron Nitride Parts for PVD Machines – Exceptional machinability, high temperature resistance, and excellent non-wetting properties make BN an ideal material for thin film deposition systems.

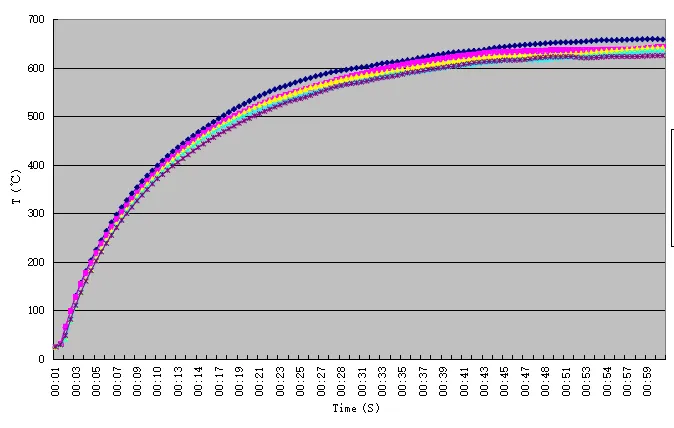

✅ Thermal Transfer Plate – Designed to provide stable and efficient heat exchange for semiconductor process equipment, ensuring uniform temperature distribution.

✅ Alumina and Aluminum Nitride Parts for Semiconductor Applications – Delivering high dielectric strength, thermal stability, and corrosion resistance for wafer processing and chamber components.

![]()

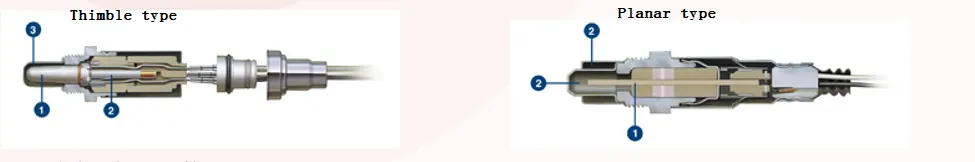

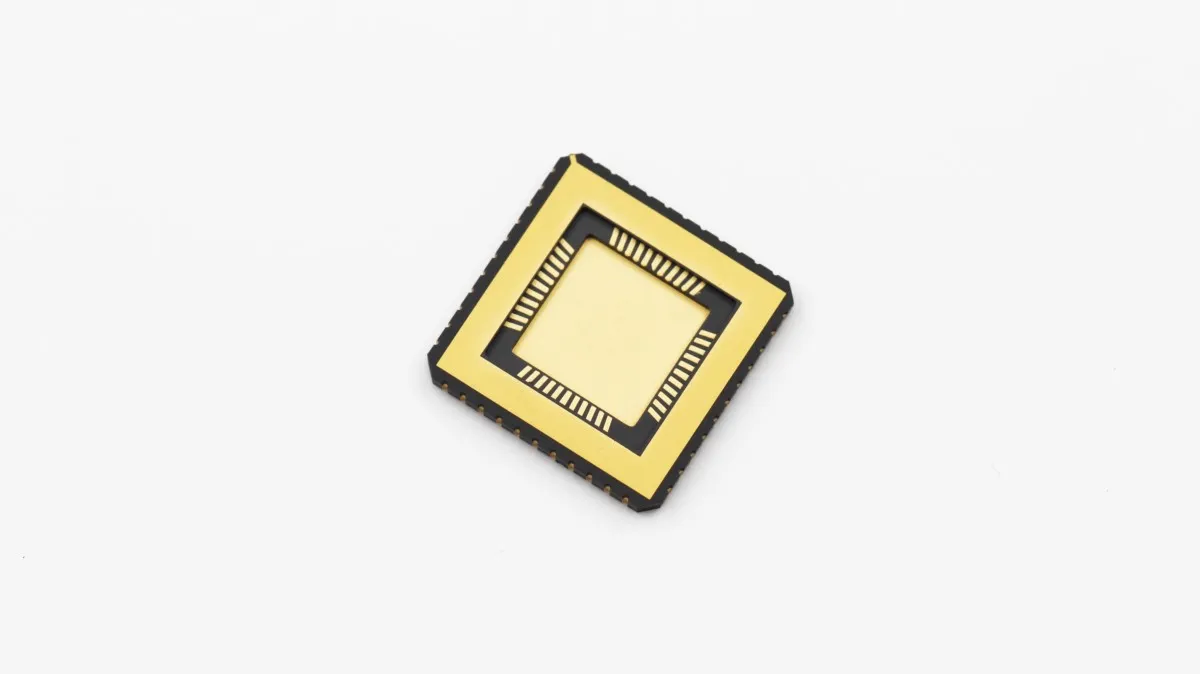

✅ ALN Cover Heater – Made from hot-pressed aluminum nitride ceramics, the ALN cover heater offers exceptional thermal conductivity (up to 210 W/m·K) and electrical insulation.

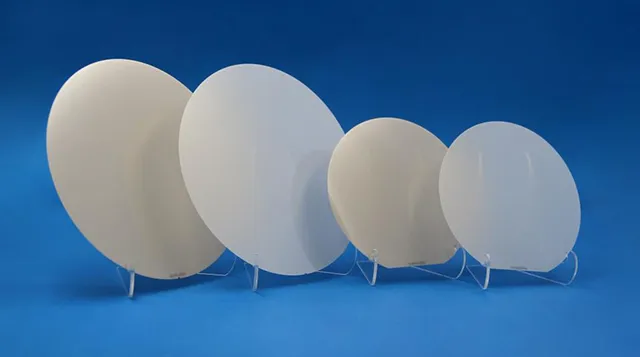

✅ Aluminum Nitride Wafer Substrates (ALN Wafer) – High-purity aluminum nitride wafers offering outstanding thermal conductivity and mechanical strength, supporting the next generation of high-power and high-frequency devices.

Driving Performance in Semiconductor Manufacturing

Innovacera’s ceramic materials are integral to critical semiconductor manufacturing processes such as PVD, CVD, etching, and wafer handling. Our boron nitride and aluminum nitride components deliver unmatched reliability under high-vacuum and high-temperature conditions, while thermal transfer plates and cover heaters ensure precise thermal control for process consistency. These solutions contribute to improved equipment uptime, reduced contamination, and higher production efficiency.

Whether your focus is wafer fabrication, deposition technology, or equipment innovation, Innovacera provides tailored ceramic solutions to meet your specific engineering requirements.

Event Details

Event: SEMICON Europa 2025

Dates: November 18–21, 2025

Location: Trade Fair Center Messe München, Am Messesee 2, 81829 Munich

Innovacera Booth: #C2/249

Innovacera will also be exhibiting at another booth during the same event — visit us at [B2 Hall 1409] to explore more advanced ceramic solutions: Innovacera Will Showcase Technical Ceramic Solutions for Electronic Manufacturing at Productronica 2025 in Booth B2 Hall 1409

Enquiry

Enquiry