When you are in Japan, you must know that the intelligent toilet is trendy, because there is one unforgettable and very human function which is the heating function. Today I will tell you the secret of keeping the intelligent toilet lid warm. Actually, it is a ceramic heater.

At present, the heating function of the intelligent toilet lid is the following: 1. Warm buttock washing function, female washing function and reciprocating cleaning function all need water heating; 2 toilet seat heating function; 3. Realise the purpose of paperless warm air drying for toilet, and the realisation of these functions requires the support of heating components.

1. The current heating mode of intelligent toilet is two kinds. One is thermal storage type another is the instantaneous water heater.

The thermal storage type is the most mainstream way of heating in an early time. It is similar to the water heater. In the intelligent toilet back, there is a storage tank, which will deposit a certain amount of water, after the heating, the water temperature will drop to natural, and when it drops to a specific temperature, the seat will heat again at a constant temperature. Because of the hot water reserves and heating speed is limited, users will feel the water temperature is not stable. And instantaneous water heater type is to heat the water flow direction, so it can avoid breeding bacteria and harm the water quality due to long-term storage of water, and more healthy.

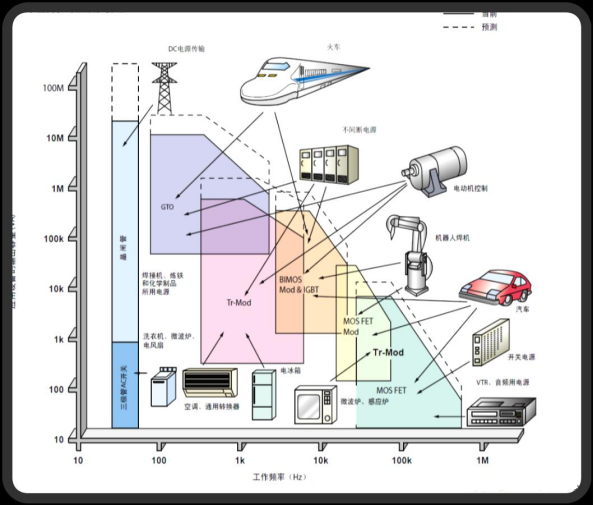

2. The heating body of the core component of the intelligent toilet generally adopts a ceramic heating body, and the preparation cost is also relatively high. At present, the common ceramic heating elements include MCH ceramic heating element and PTC ceramic heating element.

PTC ceramic heating body: ceramic PTC is composed of barium titanate (or strontium, lead) as the main component, with a small amount of rare earth (Y, Nb, Bi, Sb), acceptor (Mn, Fe) elements, as well as glass (silica, alumina) and other additives, sintered semiconductor ceramics. PTC heating element is using PTC ceramic heating element and aluminium tube. This type of PTC heating element has the advantages of small thermal resistance and high heat exchange efficiency. The outstanding characteristic lies in the safety performance, under any application will not produce such as the electric heat pipe heater surface “redness” phenomenon, thus causing scald, fire, and other safety hazards.

MCH ceramic heating element: MCH is the abbreviation of Metal Ceramics Heater, which means cermet heating element. The MCH ceramic heating element is by sintering the electric heating element and the ceramic at a high temperature to form a ceramic heating element.

Generally, metal tungsten or molybdenum-manganese paste is printed on the ceramic casting body, laminated by hot pressing, and then protected by a hydrogen atmosphere at 1600°C. The ceramic and metal sinter together to form a ceramic heating body. The advantages of the MCH heater are corrosion resistance, high-temperature resistance, long life, high energy efficiency, uniform temperature, good thermal conductivity, and fast thermal compensation Environmental requirements. And it does not contain harmful substances, comply with EU RoHS and other environmental conditions. MCH ceramic heating element is a new type of high-efficiency ecological protection and energy-saving ceramic heating element. Compared with the PTC ceramic heating element, it can save 20-30% of electricity under the same heating effect, and there is no massive problem of power attenuation of PTC for a long time.

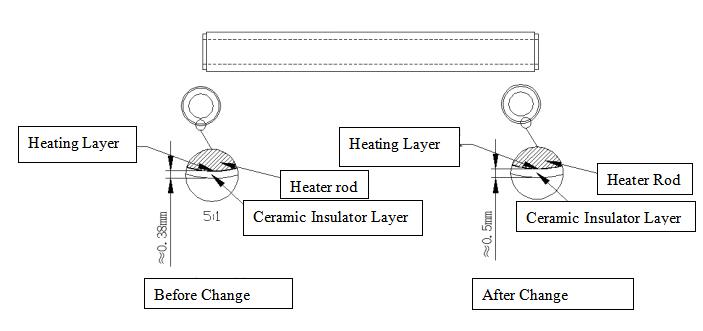

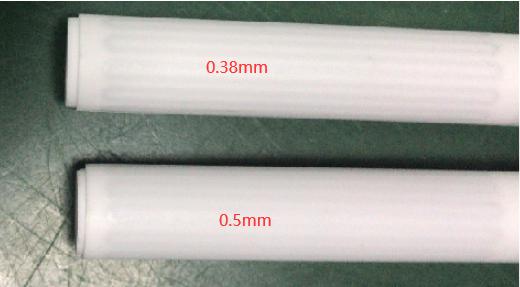

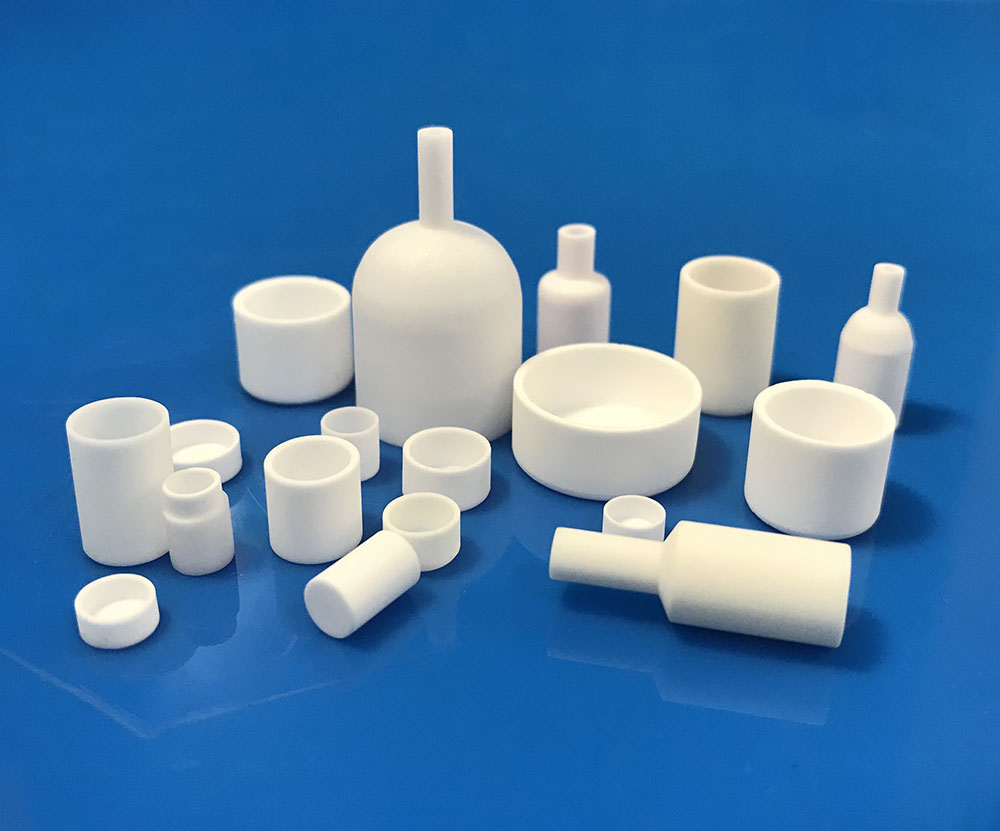

There are mainly two types of ceramics used in MCH ceramic heating elements: alumina ceramics and silicon nitride ceramics. These two ceramic materials are the most widely used in the field of electric heating elements. Both have excellent high temperature and acid and alkali resistance. However, silicon nitride ceramics have greater hardness and higher production costs than alumina ceramics. Therefore, the ceramic heating bodies currently on the market are mainly alumina, including the alumina ceramic materials, including the template drawings attached to the context.

Enquiry

Enquiry