Silicon Nitride Igniter Used for Vegetable Oil Furnace-GL02

![]()

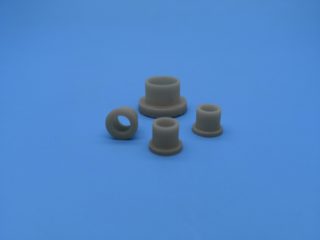

A special igniter for vegetable oil furnace was developed successfully in March 2020, which is widely used in vegetable oil boiler, and widely loved by customers.

Short Introduction:

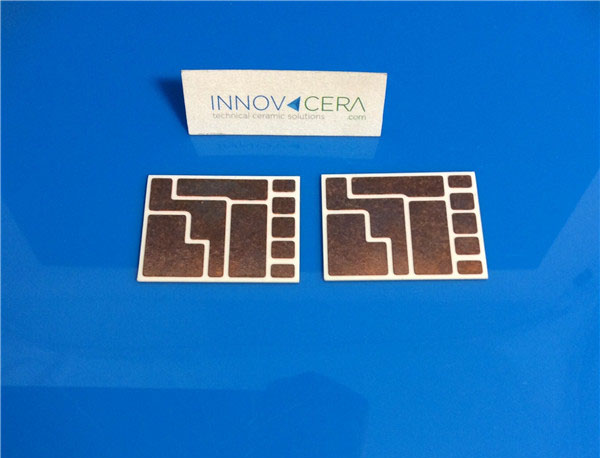

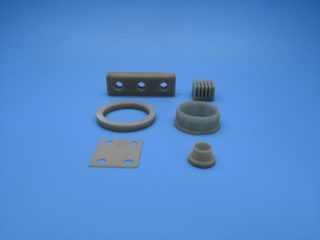

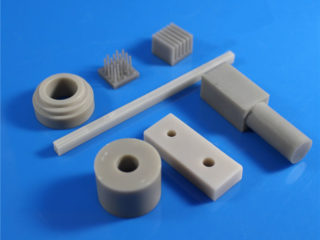

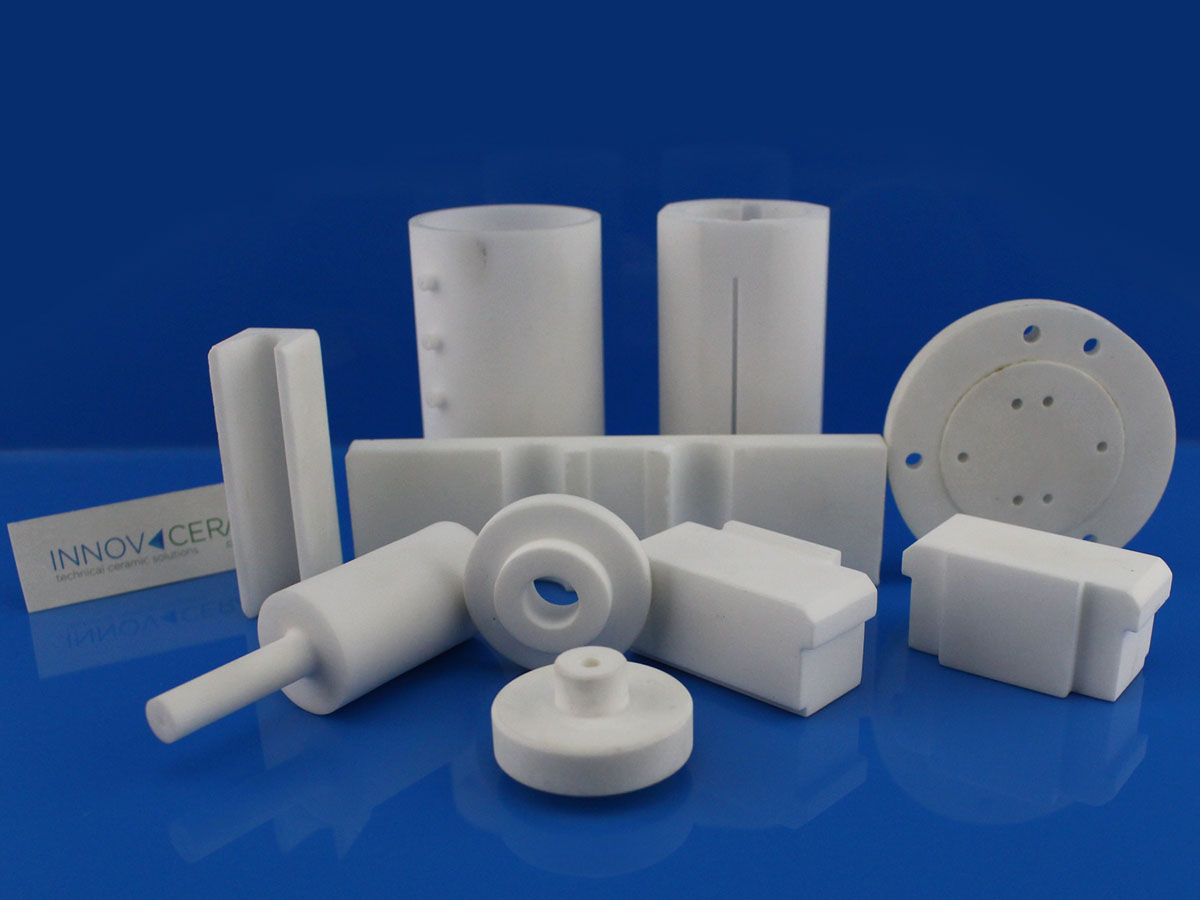

This product uses high-performance silicon nitride ceramics as the substrate, with high-temperature mechanical strength, strong thermal shock resistance, and

resistance to acid and alkali corrosion advantages. It not only has excellent insulation properties but also has good thermal conductivity.

Datasheet of the product:

| Bending strength | ≥900Mpa | RoFracture toughness | 6.0-8.0 Mpa.m1/2 |

| volume density | 3.20-3.4g/cm3 | Volume resistivity at room temperature | 1014Ω.cm |

| Relative dielectric constant | 6-7 | Thermal conductivity | 23-25W/(m-k) |

| Thermal expansion coefficient | 3.1×10-6/℃ | Hardness | HRA92-94 |

| Voltage | 220V | Power | 400W |

| Size | 80*17*3.5mm |

Performance and Feature:

Good moisture resistance and tightness;

Small size and lightweight;

Excellent thermal performance, fast temperature rise, surface temperature rises to 1100 ℃ in 15 seconds;

Has excellent electrical insulation performance;

High-performance silicon nitride material is used as the base material, which has excellent oxidation resistance, long service life, and on-off up to 100,000 times

Comparative advantages with traditional metal tube heating bodies:

Strong corrosion resistance;

Uniform heating and high heat conversion rate;

Power stability;

Strong bending resistance;

Good sealing;

Low leakage index;

High anti-penetration rate

Application:

Constant temperature vegetable oil boiler, biomass boiler, gas stove boiler, etc.

Enquiry

Enquiry