INNOVACERA’ s Silicon Nitride Ceramic Heater

Innovacera is a professional advanced ceramic materials and parts manufacturer. Ceramic heaters are our strength productions as well. And we not only have alumina ceramic igniters, but also silicon nitride ceramic igniters.

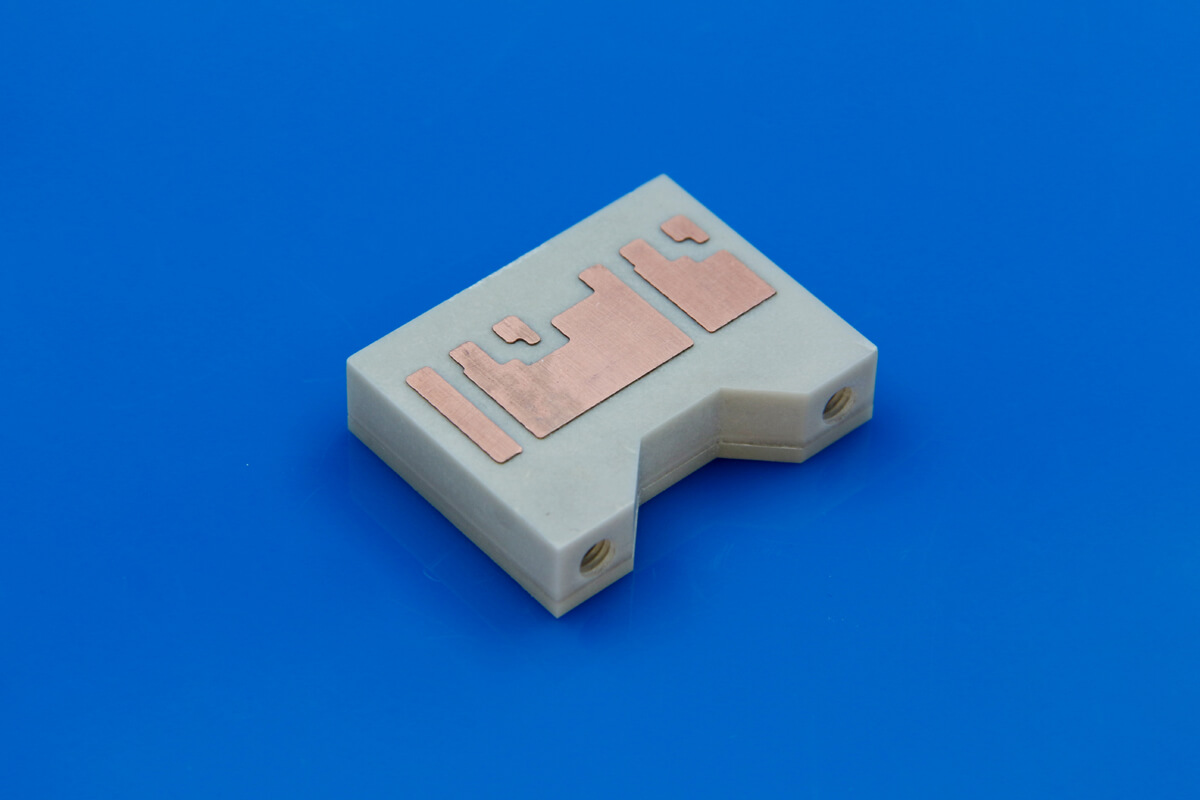

Characteristics of Si3N4 Igniters:

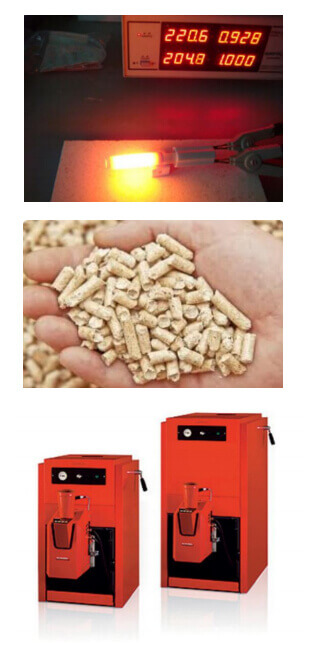

1.Silicon nitride ceramic igniter is the latest and most advanced application of hot surface ignition technology.

2.Silicon nitride has outstanding advantages:

> High working temperature

> Fast heating speed

> Compactness and solidity

> Long working life

3.The working voltage of the silicon nitride igniters extends from 4V to 240V, and the power is from 10W to 750W.

The applications of Silicon Nitride Heating Element:

1.Gas heating equipment and Water heater

2.Gas stove

3.Fuel heating equipment

4.Gas burner

5.Burners for Commercial/Research

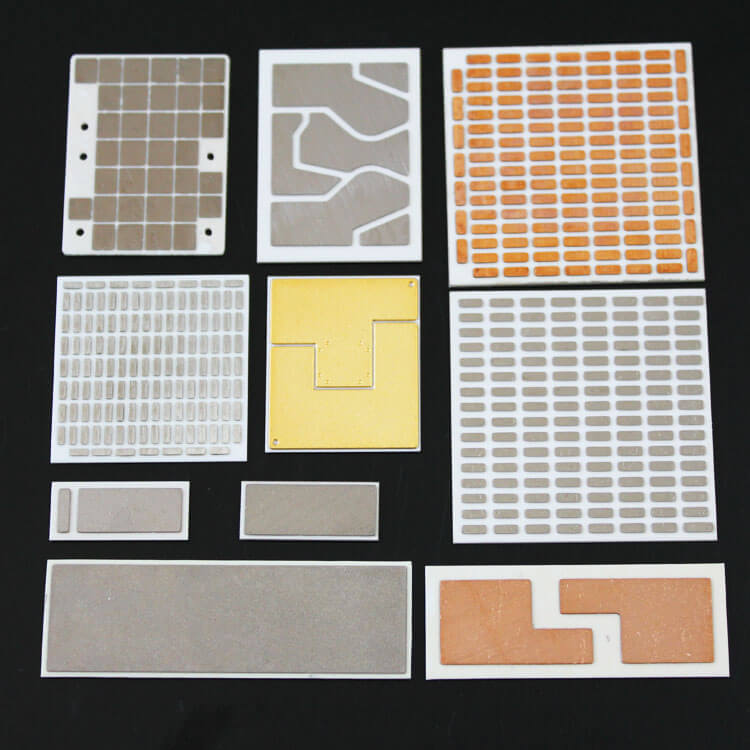

Silicon Nitride Heater’s Dimension power and input voltage are customizable according to your requirement. If you have any needs, please contact us with no hesitation!

Silicon Nitride Ceramic Heater

Enquiry

Enquiry