Rapid and Reliable Ceramic Hot Surface Igniters

INNOVACERA offers ceramic igniters for hot surface ignition systems in heating applications. These high strengths, heat resistant ceramic igniters have become an industry standard in gas heating systems. Their superior materials and rapid heating capabilities provide reliable performance over a long useful life.

Applications include:

- Gas heating systems

- Ovens/ranges

- Dryers

- And more

IGNITER PRODUCT FAMILIES

INNOVACERA offers two families of ceramic igniters, each offering different ranges of style, durability, and heat up speed to ignition temperatures — all leveraging strong material properties including:

- Low porosity

- High operating temperature

- Corrosion resistant

- Long lasting

- Easy to install and retrofit

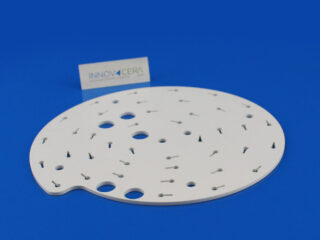

Alumina Igniter

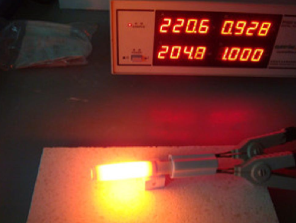

INNOVACERA’s alumina igniter can reach a permanent working temperature above 900°C. Since air can through and around inside and outside of the heater tube, heat can be transferred from both inside and outside of the heater element. It’s widely used in igniting wood chips, firewood, coal bricks or other fuel.

Advantages of Alumina Igniter:

- Permanent operation temperature reaches 1000 degree C-1100 degree C

- Extremely long lasting.Operating more than 10,000hours

- Extremely Energy-efficient.Rapid Ignition 60%-90%

- High Quality and Robust

Applications:

- Hot surface igniters (ignition of gas, oil, biomass, pellets)

- Hit air generation

- Customer-specific heating solutions.

The regular size of Alumina Igniter:

OD10.5*78mm 220V, 160-230W

OD10.5*90mm 220V, 160-250W

OD11.5*108mm 220V, 300-350W

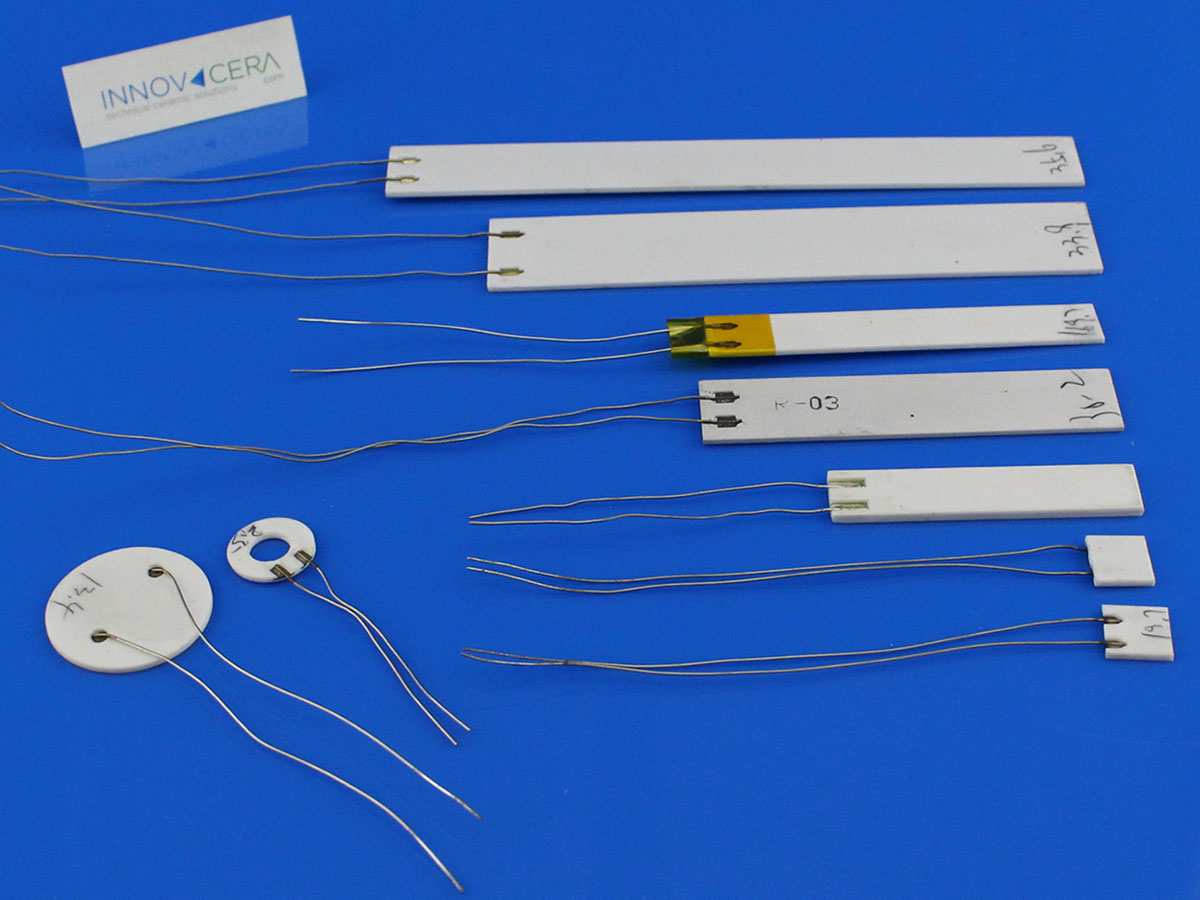

Silicon Nitride Igniter

INNOVACERA’s silicon nitride heating elements are normally rectangular in shape. These heaters have a lot operation zone up to 1000 degree C and a cold zone in the contact area. The encapsulated terminal can prevent short circuit caused by conductive contamination. They can be operated with or without a controller. Silicon nitride heater has several times the durability than that of silicon carbide products.

Performances & Characteristics:

- Electrical safety. The current leakage after the break is less than 10 mA

- High temperature resistance. Dry point up to 1300 ℃

- High surface load. Heating liquid surface load up to 78w/cm2

- Small size

- The thermal inertia is small, faster heating up.

- Long service life

- Acid and alkali corrosion resistance

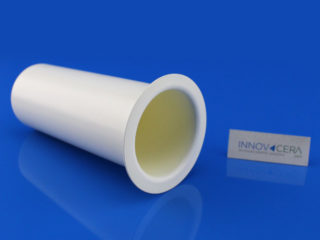

the cylindrical ceramic heaters, in combination with an extremely high surface temperature of 1000

the cylindrical ceramic heaters, in combination with an extremely high surface temperature of 1000

Enquiry

Enquiry