Boron Nitride Crucible for Vacuum Casting Molten Metals

Boron nitride exhibits a hexagonal structure and is sometimes known as white graphite, due to its lubricity, anisotropic properties, heat resistance, and high thermal conductivity. This latter property, combined with low thermal expansion, leads to excellent resistance to thermal shock. All three forms, hot pressed, pyrolytic and hot isostatic pressed, can be used at very high temperatures. However, in an oxidizing atmosphere, the maximum use temperature is 850-900°C. Hot pressed and hot isostatic pressed boron nitride are produced by densification of powder, whereas pyrolytic boron nitride is produced by chemical vapour deposition (CVD), depositing onto graphite at temperatures in excess of 1800°C.

The use temperature of boron nitride ceramic crucible in a vacuum is 1800 degrees, and the use temperature under atmosphere protection is 2100 degrees. The nitrogen or argon atmosphere is the best and has the longest life. The boron nitride crucible is resistant to thermal shock, and will not crack when it is rapidly cooled at 1500 degrees. It will not crack if it is taken out of the furnace at 1000 degrees for 20 minutes and blow and quenched hundreds of times.

Precautions for use:

1. The use temperature in the air should not exceed 1000 degrees, and the surface of boron nitride in contact with oxygen will peel off if it exceeds 1000 degrees.

2. Boron nitride is easy to absorb moisture. The crucible cannot be stored in wet areas and cannot be washed with water. It can be directly wiped off with sandpaper or scrubbed with alcohol.

3. Application direction of boron nitride crucible

Available materials:

1. Ferrous metals: iron, copper, aluminium, nickel, magnesium, bismuth, zinc, etc., alloys FE-CO-NI-SI CO-ZR-NB

2. It does not react with water or acid at room temperature. Boil with water and slowly hydrolyze to generate boric acid and ammonia

3. Rare earth, nitride

Unavailable materials:

1. Antimony trioxide, chromium Heptoxides, molybdenum trioxide, arsenic trioxide, titanium carbide, etc.

2. High-lead glass glaze melts in the air at 800-950 degrees, which will corrode BN, but it will not react under the protection of nitrogen or inert gas.

3. Boron phosphate is corrosive to boron nitride in 1400 degrees nitrogen and will react with hot concentrated or molten alkali and hot chlorine.

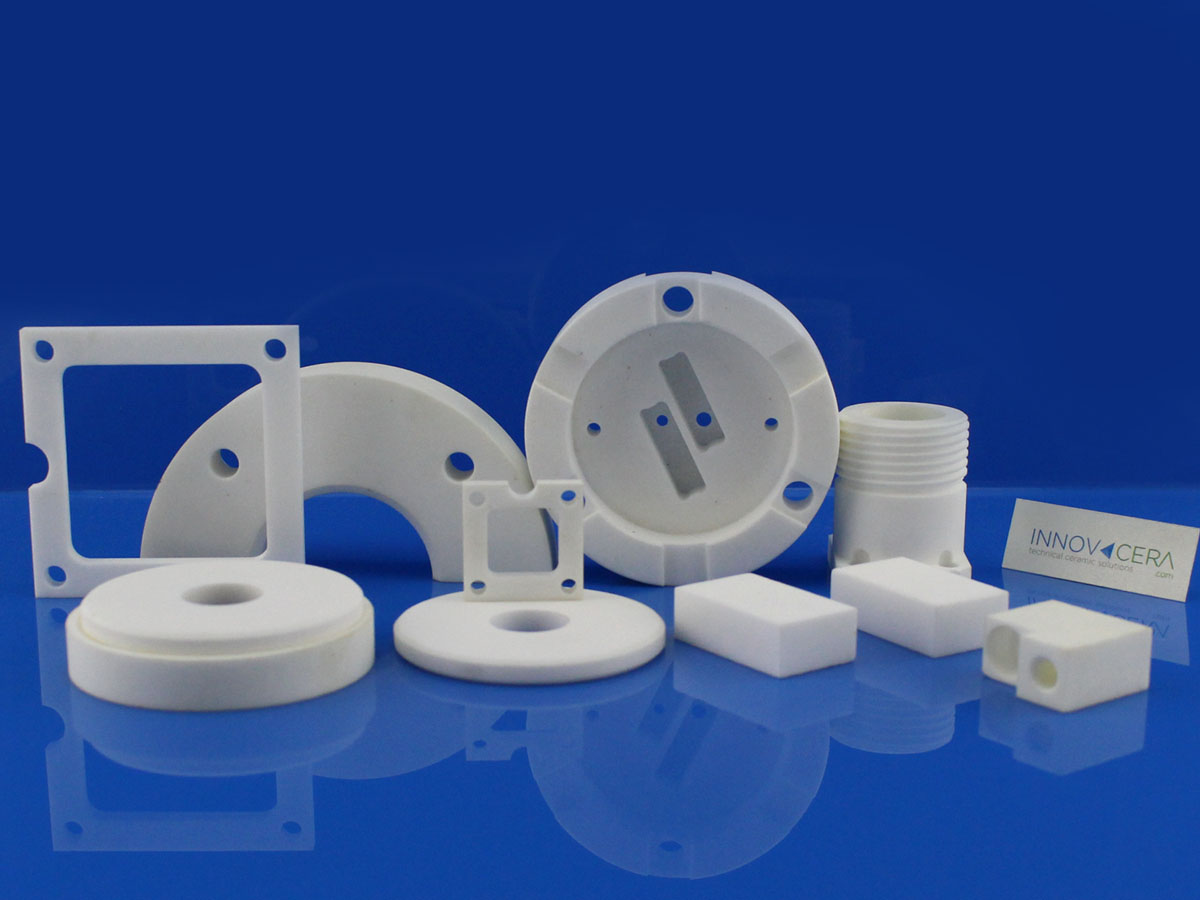

INNOVACERA supply all shapes of ceramic crucibles, welcome inquiry.

Enquiry

Enquiry